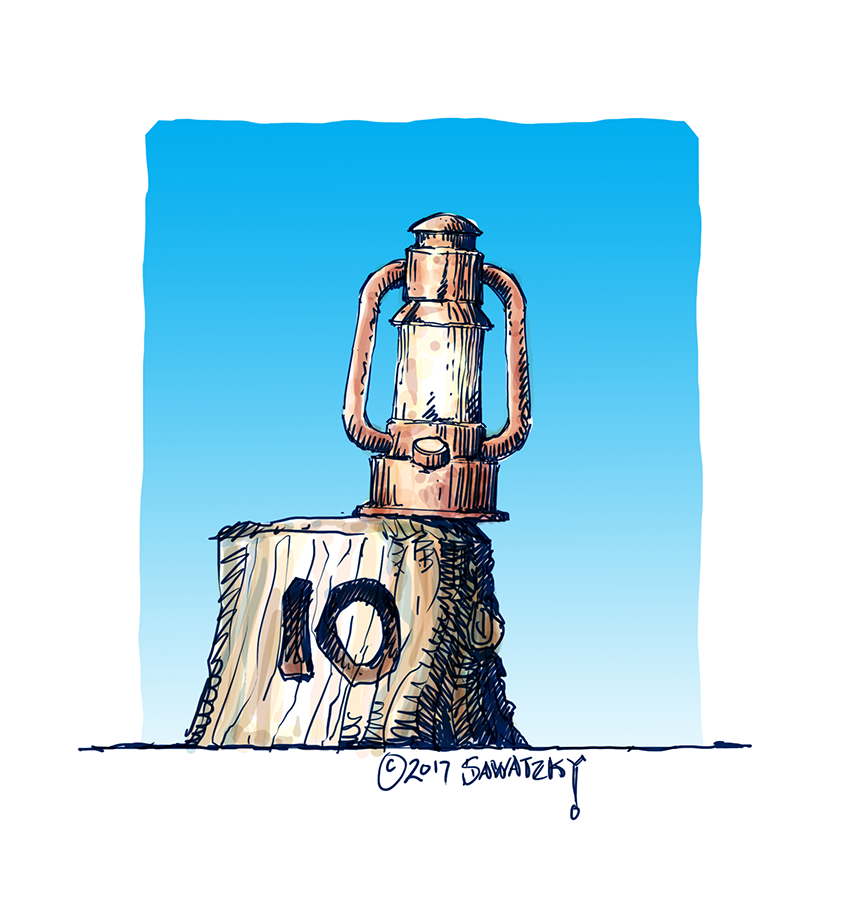

One of the good things about posting photos of our projects each day is that our customers can follow the progress from afar. On the rare occasion something is amiss, things can be quickly and easily corrected while changes are still easy. The features we are currently building are for an adventure golf with each piece to be placed on a specific hole. I inadvertently miss-numbered the lantern piece yesterday but within minutes of my posting our client contacted me with a correction. This morning it was an easy fix to cut a new number and replace the number ten with a numeral three. Our customers love to watch their pieces come together and we appreciate the constructive input along the way to make sure everything is perfect. We also finished the armature for the log feature today complete with a heavy duty cross cut saw.

Let there be light

It's fun to rummage through our parts bins and scrap steel to come up with most of the pieces I needed to build a lantern for a mini golf hole marker. The rest of the steel shapes I needed were quickly cut on the CNC plasma cutter from bits of scrap steel plate. The lantern needed to be extremely sturdy for guests who will interact with the feature will be carrying golf clubs and often aren't afraid to use them.Once complete the steel sculpture was welded to the frame of the stump armature. It won't go anywhere. The stump will be sculpted with fibreglass reinforced concrete.

Almost ready to roll.

I worked on the little tractor a little in the afternoon today and and in that time finished the handlebars, and fabricated and mounted the engine crank, muffler, gauges and throttle. Only a couple small things are left before we declare this little gem ready for paint!