It was a very big day as the crew applied and sculpted the last of the concrete for the bowling alley lane archways. Space to move around the shop, as always it seems, was at a premium. Now the crew will move on to a slightly different style of arches, ten in all, for the side wall areas.

Keeping the real world in mind

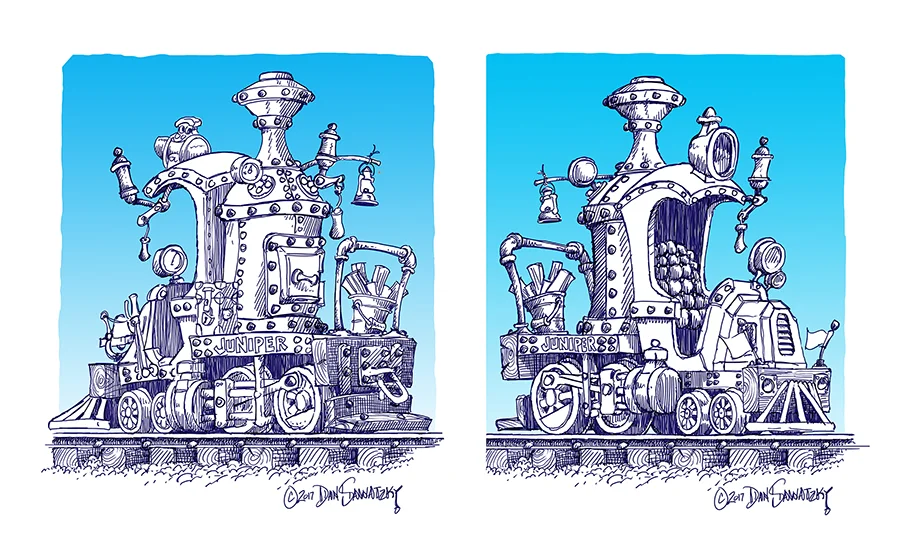

As we design and build our slightly off kilter cartoon worlds we can't forget about the real world. While we can make anything work in a concept drawing the truth is that people from the real world have to interact with the things we build. The trick is to keep those wonderful proportions and curved lines intact as we do it.

In the case of the rail inspection vehicle I am designing there are plenty of constraining elements that fight with the design intent. Real full size people need to fit relatively comfortably inside the cab. The rail gauge (distance between the rails) doesn't change. When dollars are a factor the off-the-shelf components are a whole lot less costly than custom made stuff. The train car of course needs to fit through existing tunnels and doorways. And the mechanical components and controls need to be all tucked safely inside and yet still be readily accessible for servicing. And the one concern that trumps everything is the center of gravity of the vehicle. Inevitably some compromises must be made.

But of course with plenty of creative thinking and lots of measuring, sketching, erasing, redrawing and juggling everything can work - without giving away too much of what we set out to achieve at the start. This is the fun and challenge of design.

Almost a kilometre of welded steel

To build our features there are many steps. After the design is done the first consideration is how will it be assembled, moved about the shop, lifted onto the truck and then onside. Those factors determine the structural framework inside, and the mounting and lift points. These of course all have to be tucked within the dimensions of the finished piece. The heaviest pieces of structural steel come first, then the bracing, followed by a lighter structural frame as we work our way outwards. Place steel is cut, fitted, and welded into place for the joining surfaces. Then it is on to the 'pencil rod' armature. This is 1/4" steel rod that is hand formed and welded into a grid to form the shape of the final piece. We like to block in the big areas first and then fill in the smaller spaces to form about a six inch grid to provide a sturdy framework backing for the sculpture. As we weld we constantly do the shake test by grabbing it with both hands and swinging on it. If there is any movement we add more welded steel bracing until it doesn't. Any movement will make applying the sculpted concrete very difficult. The feature also has to withstand the stress of lifting, transport and placement - even if it is moved multiple times over it's lifetime.

The first level of the PNE feature we started this week is now down to the pencil rod stage. We are about two thirds of the way around and should finish tomorrow. There will be almost a kilometre of steel in this structure when we are done - all securely welded into place. Photographs never properly show this stage but the in person the piece looks great. It is all about proportion at this point. Lots of fun detail is coming soon. Stay tuned...