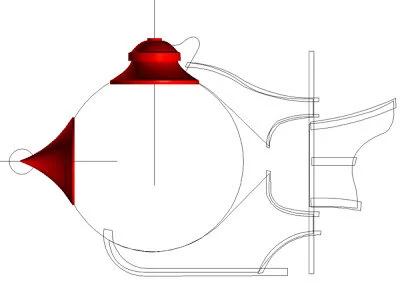

The file for the exterior of the submarine was built in EnRoute. Dad starting by tracing the shapes over a digital photograph of the sketch.

He used the profile he had created with vectors and Enroute’s revolve tool to create the shapes on the top hatch and the nose cone.

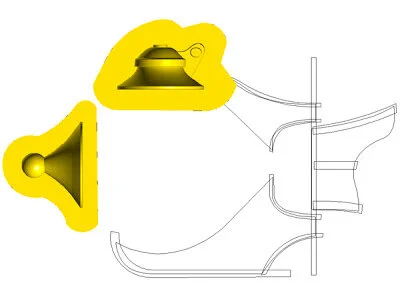

Next dad created two zero reliefs and merged the meshes to them. These were higher than his 1" thick HDU so he will need to slice them into sections later.

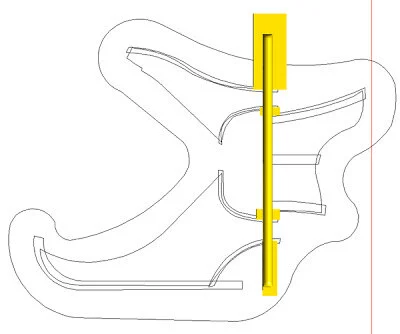

Dad prefers to build each shape individually and then merge them when he is happy with the different pieces. The hinge for the rudder was a simple rectangle domed at a 90 degree angle. Then he created four zero height rectangles and merged lowest to get rid of the bits he didn't want.

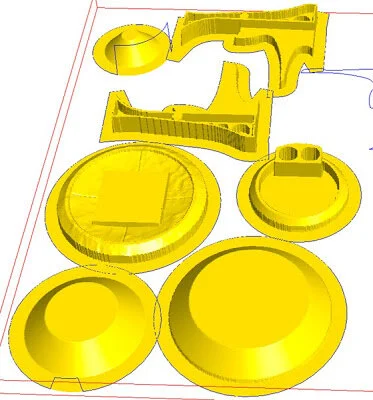

Dad built each piece, sliced and then arranged the cones then merged them to a large zero height relief. Before he applied the tool paths he checked a top view and the 3D view.

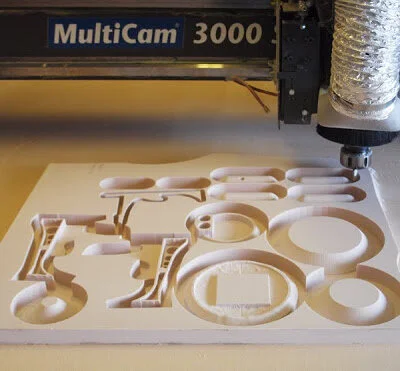

Everything looked like it should so he sent the file to the CNC router for production.