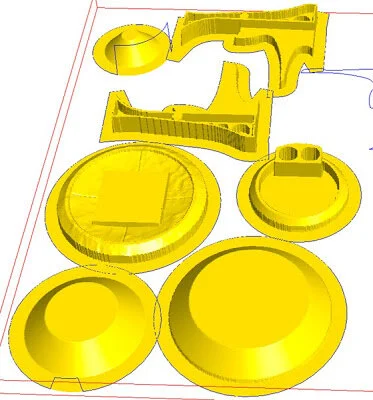

The file for the sub’s interior was created entirely in EnRoute. The bulk of it was created with vectors although dad did throw a texture bitmap on the bulkhead behind the seat. The nose cone was sliced into sections in order to fit inside the 1" HDU. He carefully left spots for the LED lighting modules.

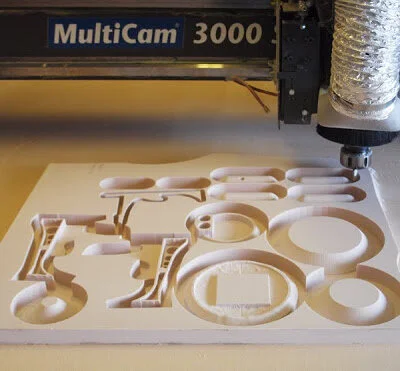

The pieces were roughed out with a 3/8" ball nose bit on the CNC router (by no coincidence our router is a MultiCam), then followed with a fine pass and a 1/8" ball nose bit.

Before dad cleaned the edges he test fit the various pieces.

Once the edges were cleaned up and the dust blown off dad glued everything up with a quick set epoxy. Then it was time for the moment of truth... would it all fit inside the glass bowl?

He needn't have worried as everything fit perfectly. In the next instalment, we will start work on the sub’s exterior.